3D printing, also known as additive manufacturing, has come a long way since its inception in the 1980s. Over the years, this technology has evolved rapidly and has found applications in numerous fields, including aerospace, healthcare, automotive, and consumer products. As 3D printing continues to develop, it is set to become a cornerstone of future manufacturing, enabling faster production, reduced waste, and greater customization.

How Does 3D Printing Work?

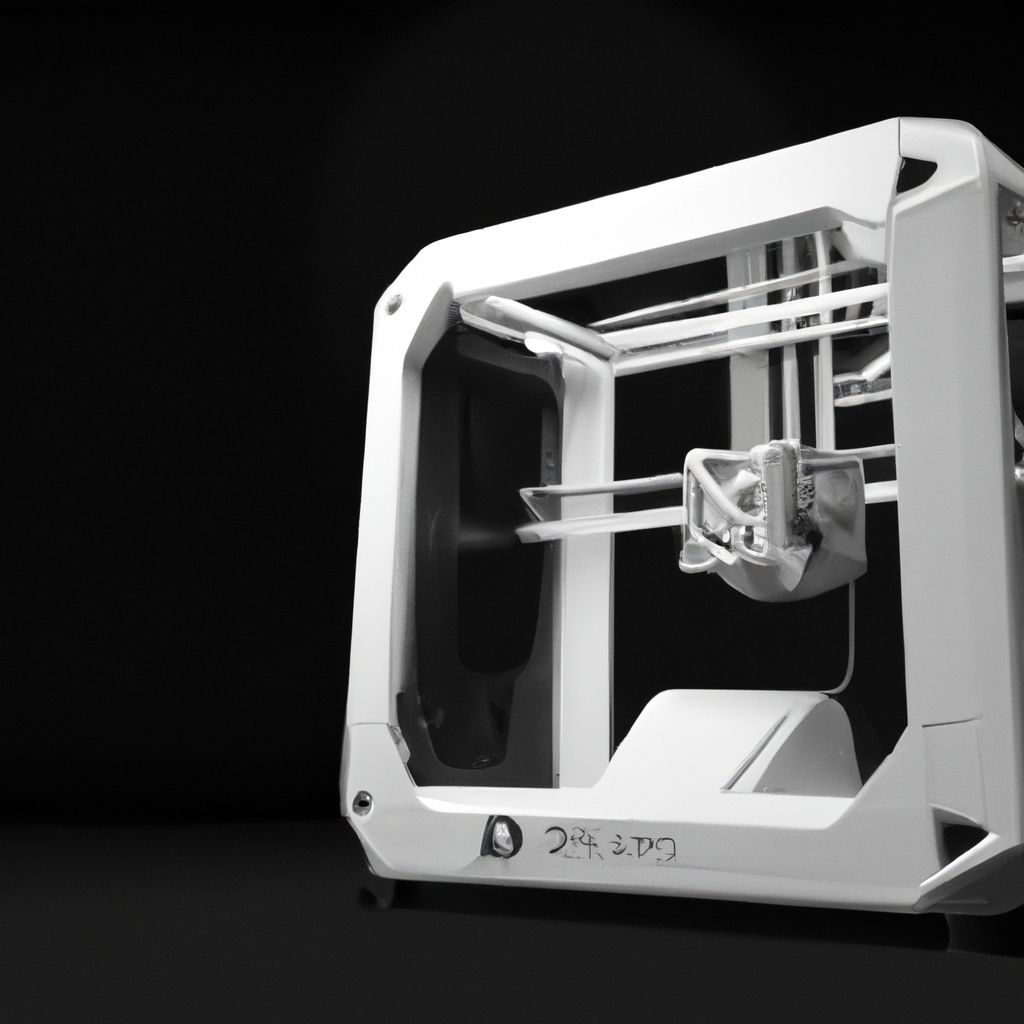

3D printing involves creating three-dimensional objects by adding material layer by layer, following a digital blueprint or model. The most common method of 3D printing is Fused Deposition Modeling (FDM), which involves extruding a thermoplastic material through a heated nozzle. The material hardens upon cooling, allowing for the creation of complex shapes and structures. Other 3D printing techniques include Stereolithography (SLA), which uses a laser to cure liquid resin, and Selective Laser Sintering (SLS), which fuses powder particles together using a high-powered laser.

Applications of 3D Printing

3D printing has found diverse applications across multiple industries, including:

- Healthcare: 3D printing is revolutionizing the medical field by enabling the production of customized prosthetics, surgical guides, and even 3D-printed organs.

- Aerospace: Lightweight 3D printed components are increasingly being used in the aerospace industry to reduce weight and fuel consumption, while simultaneously improving performance and durability.

- Automotive: The automotive industry is exploring the potential of 3D printing for rapid prototyping, manufacturing customized parts, and even creating entire vehicles.

- Consumer Products: 3D printing has made it possible for entrepreneurs and designers to create unique and customized products, ranging from jewelry to home décor and fashion accessories.

"The potential of 3D printing is enormous – it could revolutionize industries, empower individuals, and change the way we think about manufacturing and design."

The Future of 3D Printing

As 3D printing technology continues to advance, the possibilities for its applications are seemingly limitless. Some of the future prospects include:

- Sustainability: 3D printing has the potential to reduce waste by using only the required amount of material for each project, and by recycling and reusing materials from previous prints.

- Mass Customization: The ability to produce customized products on demand could give rise to a new era of personalized manufacturing, allowing consumers to own products tailored to their specific needs and preferences.

- Disrupting Traditional Supply Chains: Decentralized manufacturing enabled by 3D printing could shorten supply chains, reduce transportation costs, and increase efficiency.

- Bioprinting: The field of bioprinting holds tremendous promise for the future, with the potential to create 3D-printed organs and tissues for transplantation and research.

- Construction: 3D printing has already demonstrated its potential in the construction of buildings, with some companies experimenting with large-scale 3D printers to create entire structures.

In conclusion, 3D printing is revolutionizing the way we think about manufacturing and design. As technology advances, we are likely to see even more innovative applications, pushing the boundaries of what is possible and creating a more sustainable, customized, and efficient future.